When it comes to choosing the right concrete forming panel for the job, there is one point that builders need to be very aware of, says Olympic Panel’s Hal Studer:

When it comes to choosing the right concrete forming panel for the job, there is one point that builders need to be very aware of, says Olympic Panel’s Hal Studer:

“This is not your grandfather’s concrete mix you’re working with today.”

Concrete mixes are now more highly alkaline than before. “The most expensive ingredient in concrete is cement,” Studer explains. “So it’s pretty common now for other materials to be added to concrete mixes—things like fly ash from coal burning power generating plants and blast furnace slag from steel manufacturing—that reduce cost and also improve concrete properties.”

To create the type of high-strength, fast-set concrete required by many new high-tech buildings, Studer says, reducing the amount of water in the mix is also critical. “When you reduce the amount of water in concrete mix, you increase the strength, at least up to a certain point.”

To create the type of high-strength, fast-set concrete required by many new high-tech buildings, Studer says, reducing the amount of water in the mix is also critical. “When you reduce the amount of water in concrete mix, you increase the strength, at least up to a certain point.”

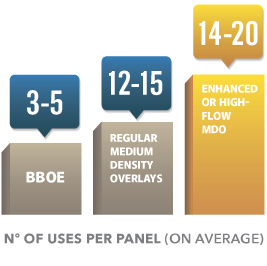

The downside? These mixes raise the alkalinity of concrete. And that’s tough on conform panels. BBOEs will give 3 to 5 uses per panel on average; regular medium density overlays will yield 12 to 15 uses each. But with an enhanced or high-flow MDO, builders can get 2 to 5 more uses out of each panel than with regular MDO, thanks to an overlay that is more abrasion- and alkaline-resistant.

Arclin’s Enhanced Flow Medium Density Overlay uses a slightly different resin—and much more resin—than standard panels, giving it greater resistance to the alkalinity of modern concrete mixes. The more resin in a panel overlay, the longer the panel lasts. And, says Studer, “the performance of these panels is more consistent than that of BBOEs.”

Even when MDO panels are priced higher than BBOEs, the cost per pour is reduced by using the engineered panels, according to Arclin’s Gordon White. “If you get 5 re-uses out of BBOE, the cost per pour is about $5,” he explains. “With a standard MDO panel, you can get 15 to 20 re-uses, and the cost per pour goes down to as little as $1.75 per pour, depending on the job and the type of panel used.”

White goes on to say “In recent independent test pours, performed by Nox-Crete,, high-flow panels with Arclin’s Enhanced Flow overlays outperformed the competitive overlay that has been the industry standard.”

These tests used a highly alkaline concrete mix design with a water-to-cement ratio of 0.33. While Arclin’s Enhanced Flow 3369 showed little deterioration after 15 pours, the competitive overlay developed surface cracks after 5 pours and was worn out before the 15th pour White explains.